SpeedyLiner System

SpeedyLiner system consists of a resin and liner for UV LED curing in laterals. UV LED technology allows contractors to optimize their operations by increasing working efficiency at the job site up to six times, reaching (in some cases) curing speeds of 1.3 m/min. SpeedyLiner system is a polyurethane-coated polyester felt, to be impregnated with a smell-free styrene-free vinyl ester resin. The liner is flexible so it can negotiate 90-degree bends without loosing mechanical characteristics after curing.

SpeedyLiner System

Resin and liner system for fast UV LED curing in laterals

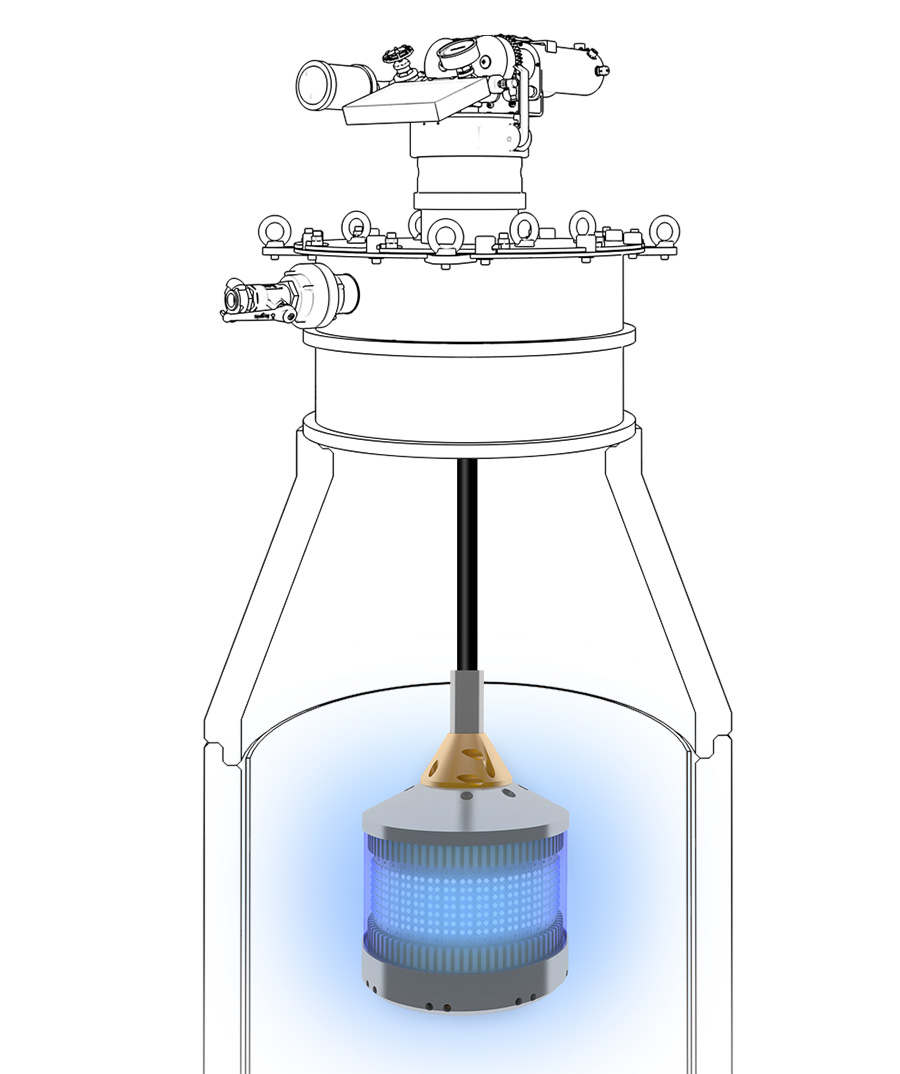

The SpeedyLiner system has been specifically designed to work with SpeedyLight's curing wavelength. Long-wave ultraviolet radiation is emitted by the LED head, exciting special chemicals in the vinyl ester resin to harden the liner.

The liner carrier is based on synthetic polyester felt (SF) coated with a polyurethane (PU) film that ensures the necessary waterproofness and flexibility during the inversion process, allowing negotiation of 90-degree bends and reducing fold lines in curves. The PU coating is transparent to most of the ultraviolet radiation spectrum, but particularly long wavelengths (400 nm). The resin chemistry is smell-free, a convenient characteristic for jobs where people work or live nearby.

Liner can be impregnated either at the job site or at the customer`s impregnation facility. In both cases, traditional impregnation tables can be used. The styrene-free vinyl ester resin is supplied in a single component, so there is no need to mix resin and hardener, which avoids extra work and dosing risks.

Visible light includes some energy in the range of 400 nm. This means that an impregnated liner exposed to ambient light may begin the curing process. To avoid this, both the impregnation (and storage), should happen in a darkroom or in a specially illuminated area, avoiding light in the sensitivity range. Once the liner is impregnated, it can be stored at the customer's facility for up to several months, depending on the ambient temperature. In worst cases, with temperatures above 20ºC, shelf life could be reduced bellow 4 weeks.

SpeedyLiner system delivers excellent mechanical characteristics, providing convenient Young modulus and break strength over the short term, as well as limiting creep factor during the lifetime of the cured liner.

SpeedyLiner is available in two thicknesses, 3.0 and 4.5 mm, and in diameters that vary from DN100 to DN250 mm. This covers most lateral renovation needs. SpeedyLiner is a flexible yet robust product that fulfils today’s CIPP demands.

SpeedyLiner Product Range

| Diameter | Dry felt thickness |

|---|---|

| DN100 | 3 - 4.5 mm |

| DN125 | 3 - 4.5 mm |

| DN150 | 3 - 4.5 mm |

| DN200 | 3 - 4.5 mm |

| DN250 | 3 - 4.5 mm |