LEDRig

LED technology for a more efficient UV glass-fibre liner curing.

LEDRig family of curing devices are designed for use with glass fibre reinforced polymer (GFRP) liners in the rehabilitation of sewer networks. Sewertronics’ patented cooling technology allows high efficiency of the LED modules, improving overall working and curing times compared with the traditional UV lamp systems.

LEDRIG significantly reduces the electrical power requirements and the cost of ancillary equipment. Use Sewertronics’ online reporting application to create your own curing reports from a tablet or hand-held device whilst on site.

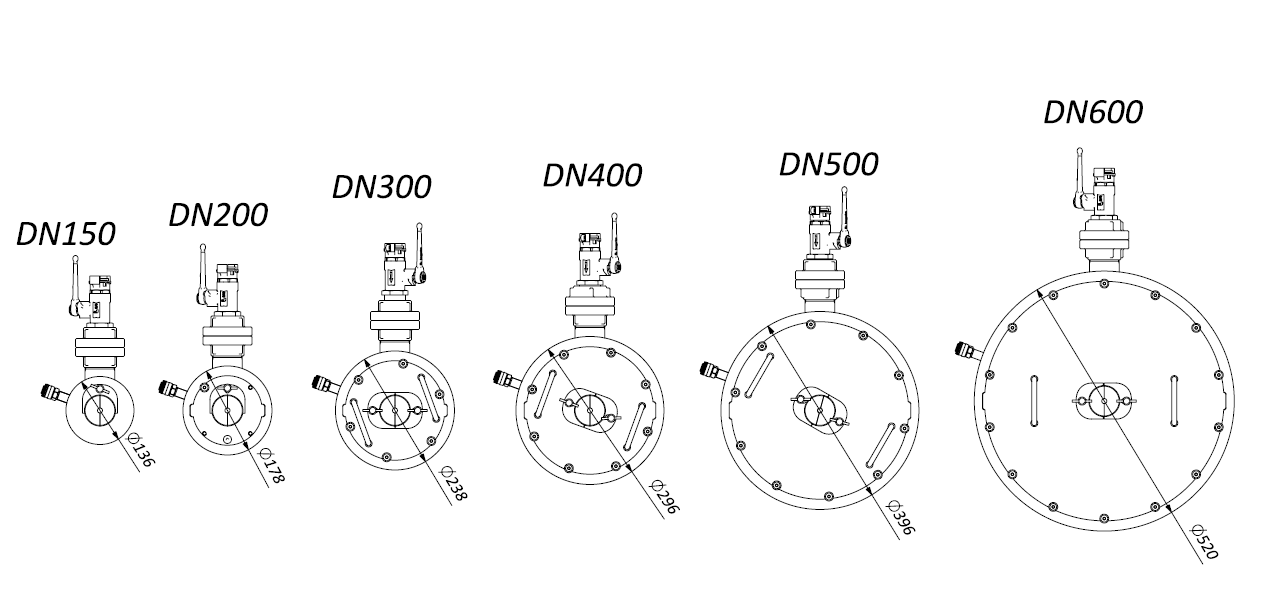

LED Rig works in dn 150 mm up to dn 600 mm only with GRP UV liners and it is compatible with our Spectra Dive for manhole rehabilitation.

LEDRIG presentation videos

A brief introduction to the Sewertronics LED solution for UV glass-fibre liner curing.

UV LED Advantages

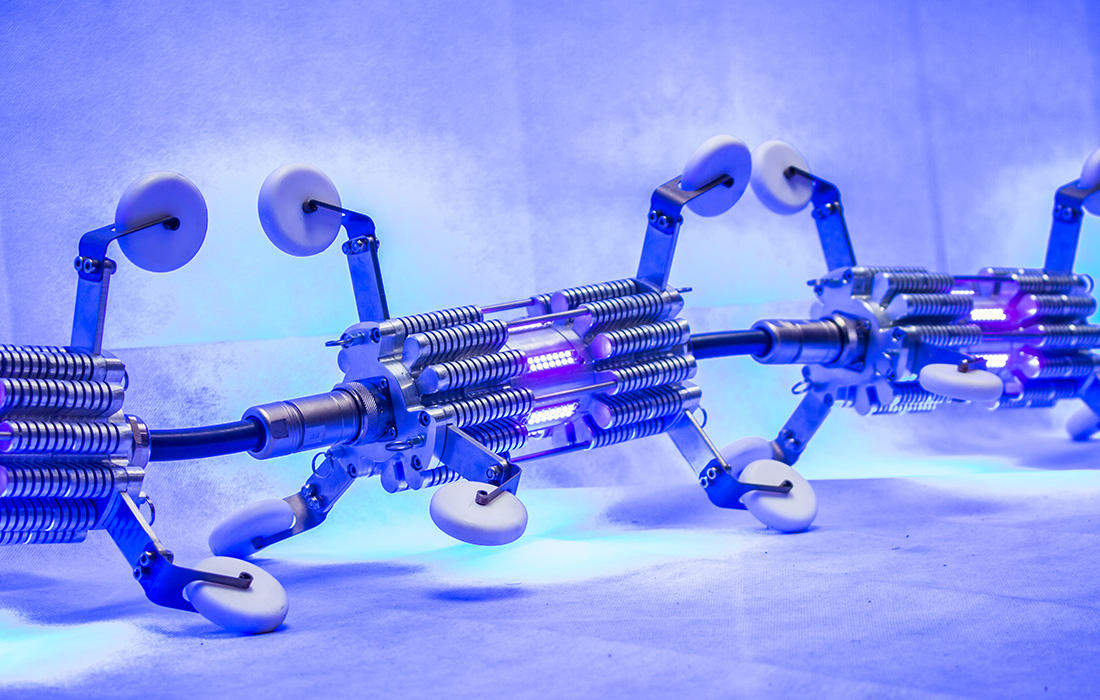

Smart and efficient UV LED light radiation modules

Hi-efficiency LED modules take the best from every W of energy, limiting unproductive heat and minimizing the size of the power supply unit required, while simplifying your ancillary equipment on site.

LED ON, LED OFF. No ignition spacing.

No wasted time on lamps ignition spacing. Classic UV lamp solutions are forced to set sequential start-up due to the large amount of power drawn (peak) at lamp ignition. All LEDRIG modules are turned ON at the very same time, saving precious time on every job.

Switch LED off & head back home.

UV LED modules do not reach dangerous working temperatures. As soon as you are done with your curing job, you are ready to take the unit off the manhole and go back home. Another time saving factor to become more effective in the field. Cure more liners in a simpler and lighter way.

LED Curing is efficient

No ignition spacing

Optimized curing speeds

No injury risk due to hot parts

Does not require a large generator

Save time at the job site

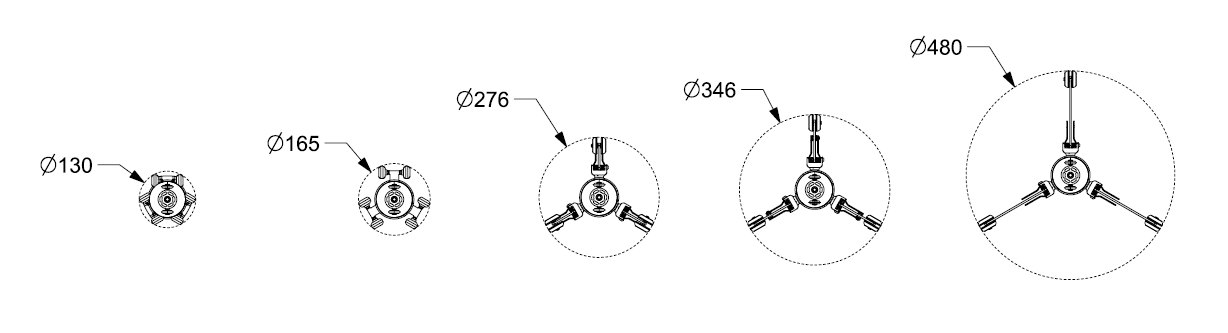

UV LED curing from DN150 to DN600

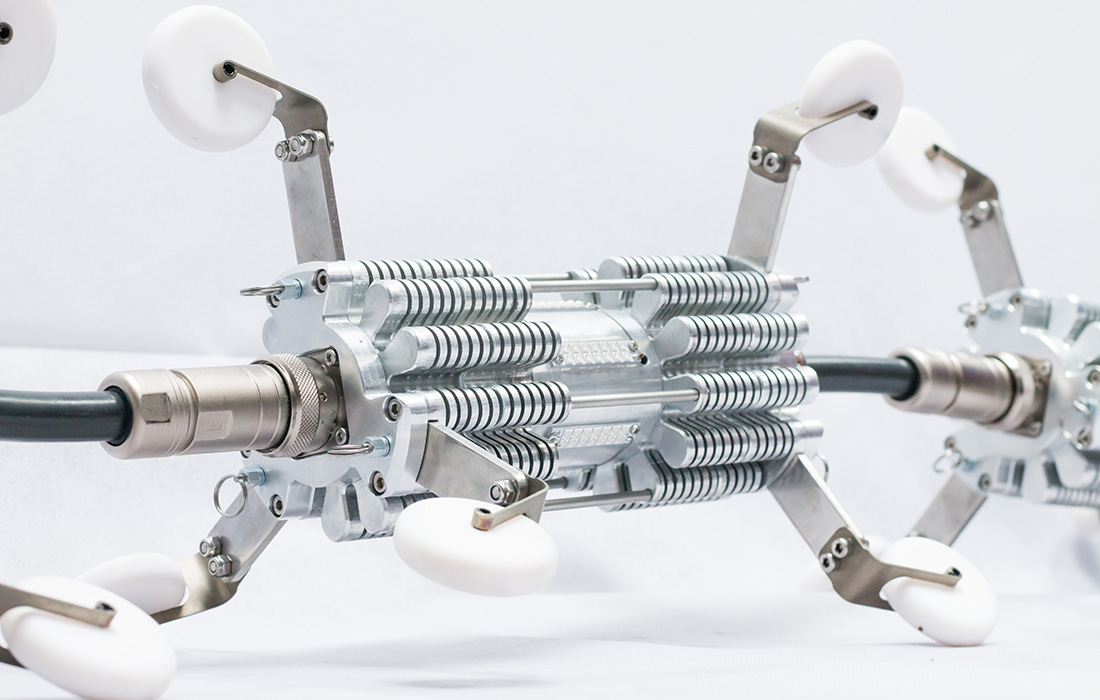

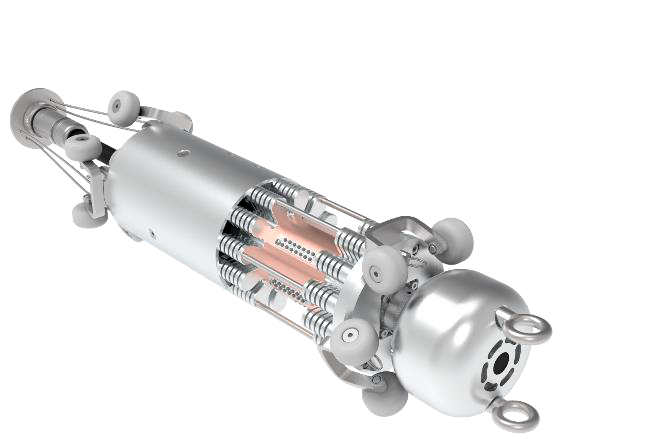

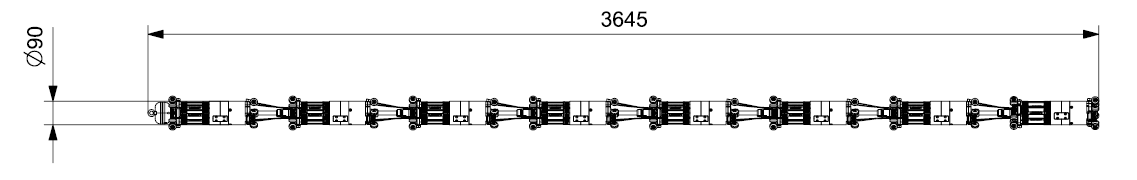

The LEDRig system is a glass fibre curing solution for diameters ranging from DN150 to DN600. The high efficiency of UV LED technology means that electricity consumption can be reduced, while the equipment can be more portable and easier to use. Its modular design allows to implement different number of UV LED modules to adapt the unit to the diameter of the pipe.

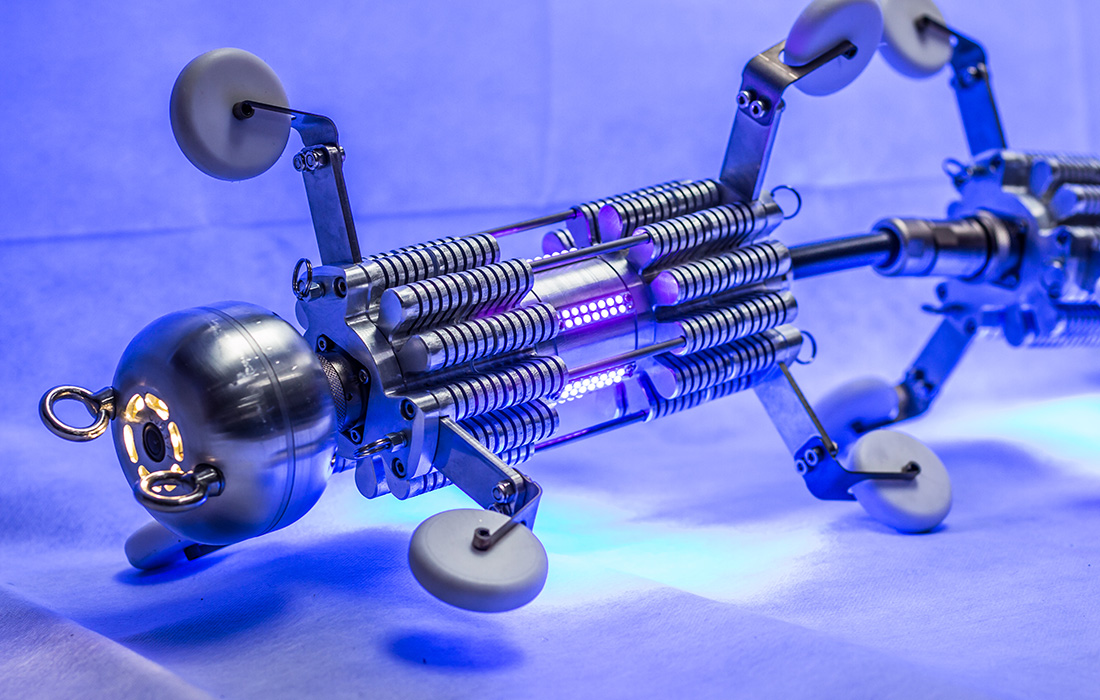

LEDRig has a 200 m long umbilical cable mounted on a reel fitted with wheels so that it can be transported to the work site. A compact control unit integrated in the cable reel supplies power to the eight UV LED modules that make up a compact array. LEDRig is suitable for application in diameters ranging from DN150 to DN600.

Modular design

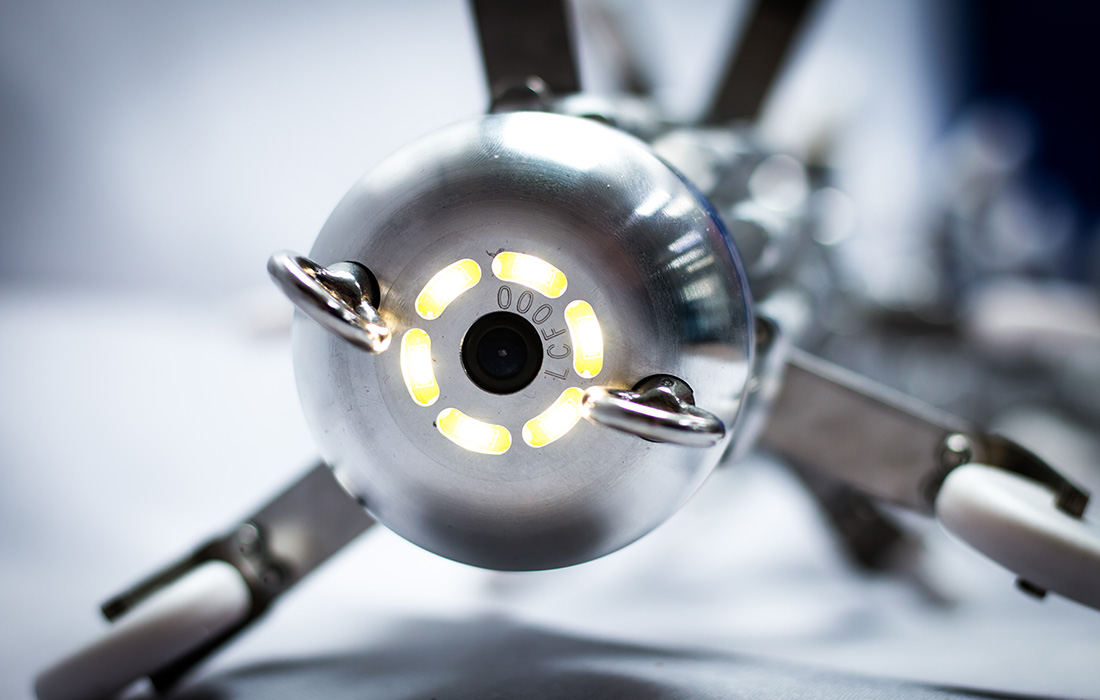

The LEDRig UV LED modules are designed to be interconnected independently: the unit can control from 4 single modules up to 8 modules, including a front and rear camera modules.

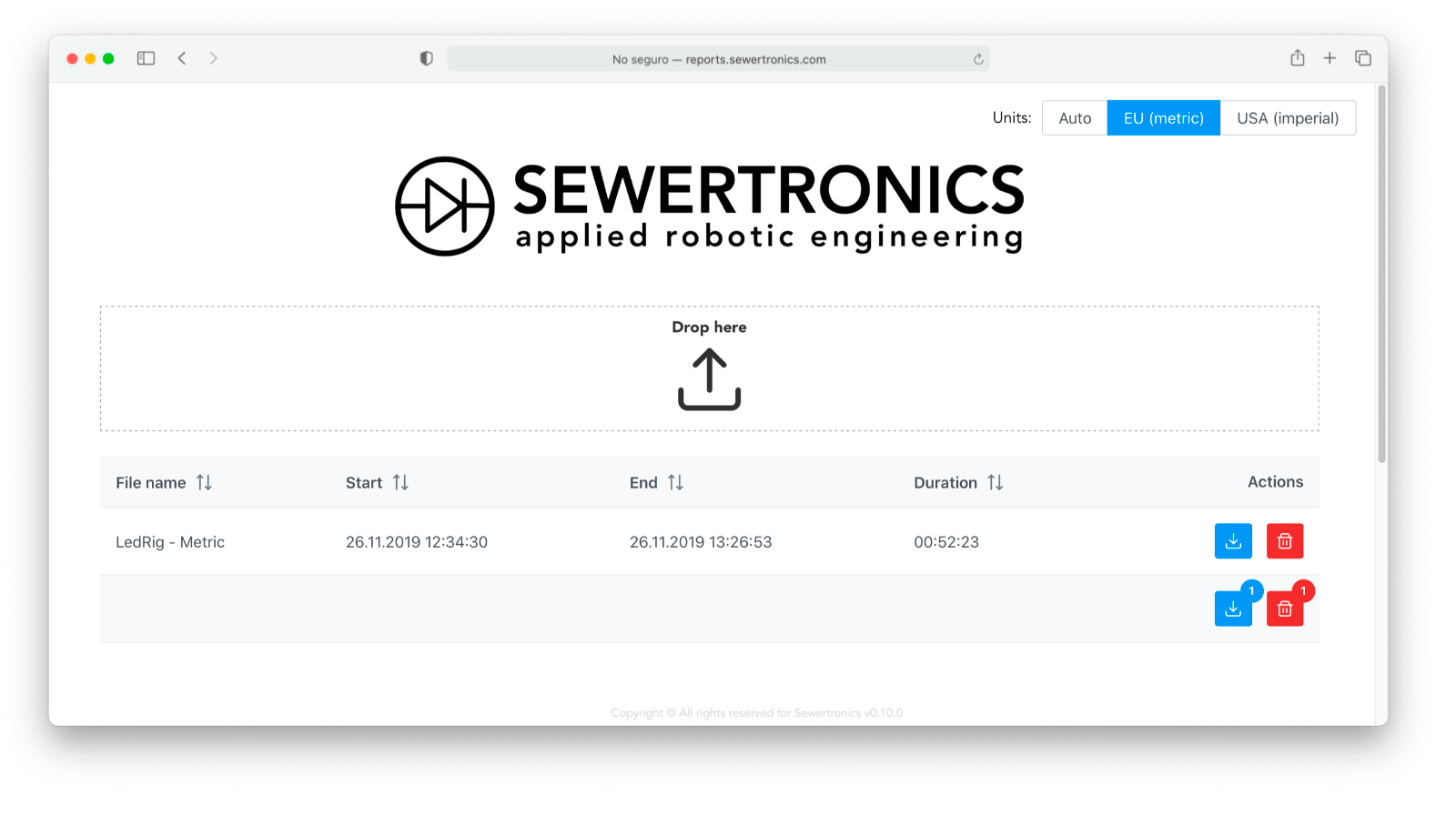

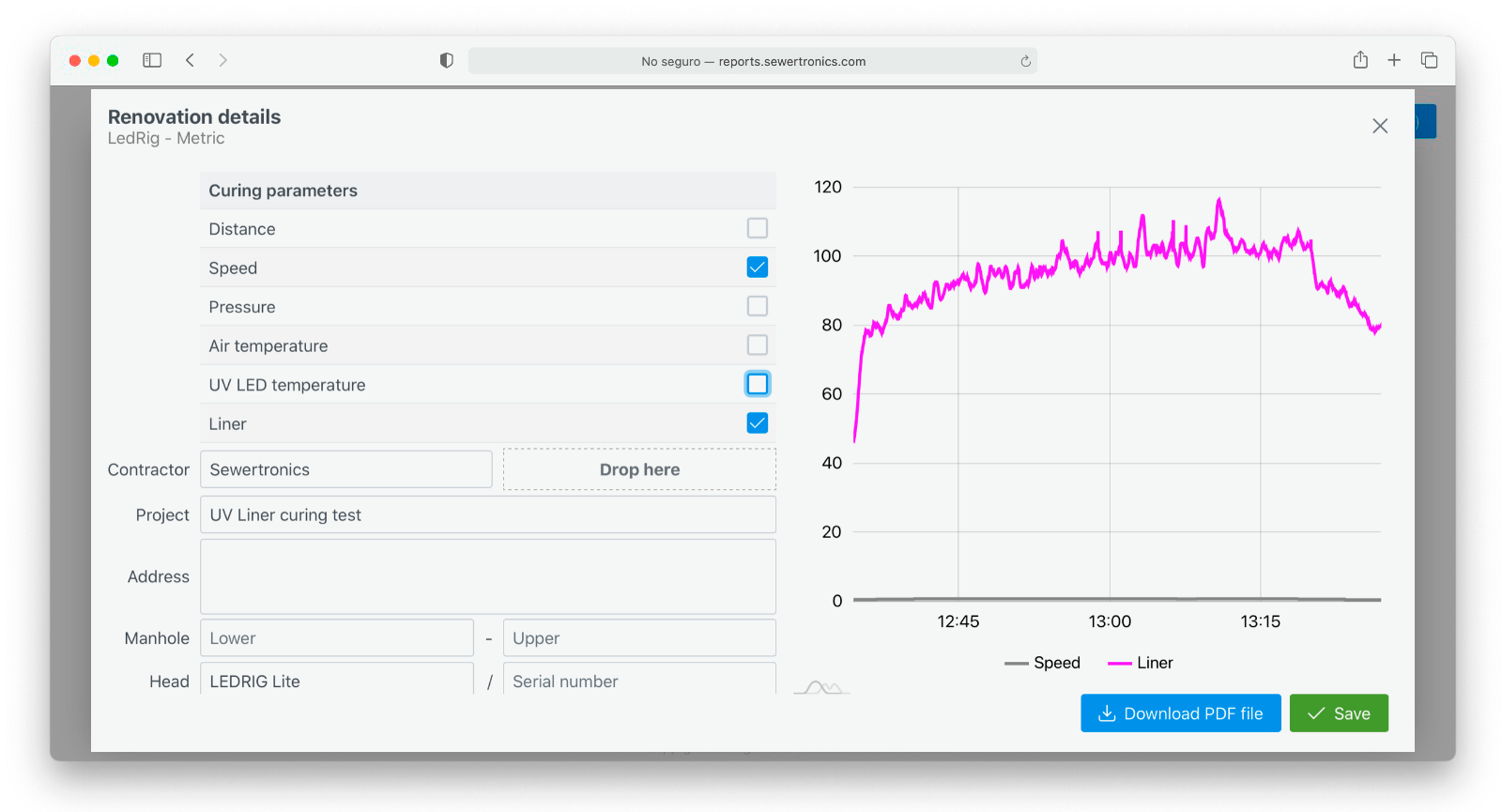

On-Line reporting

LEDRig units record & store the main data from every curing job. Our online reporting feature, easy accessible via PC or handheld device with an internet connection, is a web based system that produces an instant reports that can be adopted and personalized to your needs, that includes: name of the contractor, client, project name, address, time & hour, curing time, LED head, start-finish manholes and contractor/client logo. Curing parameters can be all combined into a single report or addressed individually - air pressure, air temperature, LED temperature, curing speed, distance etc.

The right side of the screen displays a preview of the report. The left side displays a number of settings and all curing parameters to choose from. The final output report is a pdf file that can then be sent to your client or just saved for your own company records.

Curing speeds

The LEDRig curing system is designed to be versatile and the same time offer optimal curing speeds for its size and weight. These speeds will depend on the liner diameter and thickness. All these values are provided as a guide and may vary significantly depending on the type of liner and other conditions on the job site.

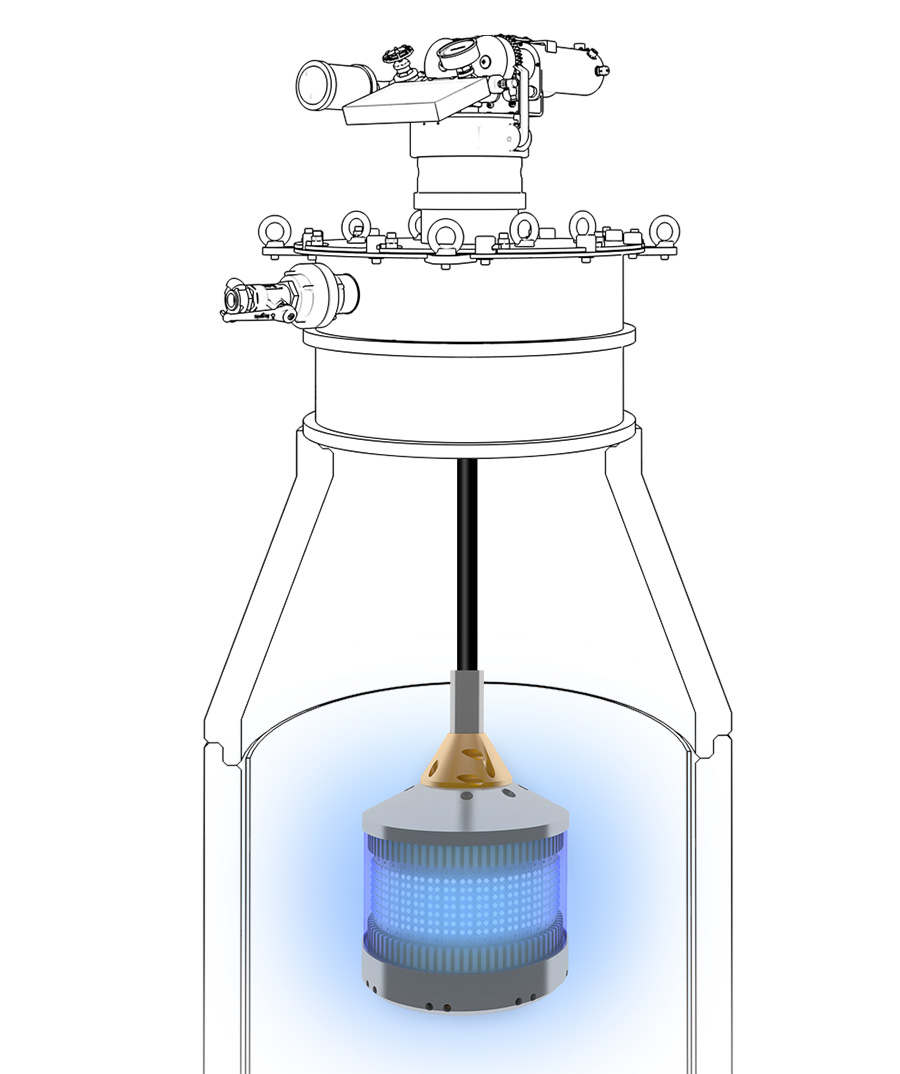

Patented cooling design

LEDRig features a patented design for the cooling of the LED curing modules. A set of especially designed lobes and fins to dissipate the heat produced by the LED. The number, dimensions and shape of these lobes have been studied to ensure optimal transfer of energy to air in the conduction. This is normally done by compressor which also provides with the necessary pressure to elevate the liner to its correct position before curing.

LEDRig System Specifications

UV LIGHT SOURCE |

|

|---|---|

| UV light source | UV LED |

| UV-C peak wavelength | 400 nm |

| Lamps Life (60.000 cycles@15 m) | 1000 h |

PHYSICAL |

|

| Dimensions (LxWxH) | 2459x90x90 |

| Total Weight | 18 KG (without centering skids) |

| Material | Aluminium & Polyamide |

WORKING DIAMETERS |

|

| DN | DN150-DN600 |

| Core Sensors | Internal Core Temp Sensor, Power Control (Optional) |

| Liner Temp Senor | IR contactless Sensor (up to 4 – Optional) |

| Other Parameters Sensor | Pressure Sensor, Air Temp Sensor |

| Live Footage | Front & Rear CCD camera with large aperture lens & 150-degree field of view |

PHYSICAL |

|

|---|---|

| Dimensions (LxWxH) | 1121 x 833x 1515 cm |

| Total Weight | 225 kg (incl. 200 cable) |

| Material | Chassis based on stainless steel, aluminium, ABS |

| Support | Structure with 4 wheels |

COMPUTER |

|

| PLC | Siemens |

DISPLAY |

|

| Main Monitor | 10” installed within the C.U |

CONNECTIVITY |

|

| WI-FI connectivity | 2,4 GHz |

| Mode | AP |

| Internet Access | Socket RJ45 WAN, Mobile tethering via USB |

SAFETY |

|

| Auto-stop function | Yes |

| Emergency Stop | Yes, Emergency Stop Button installed within the Control Unit |

| Power | Additional RCD switch |

POWER REQUIREMENTS |

|

| Voltage | 110 – 230V 50/60 Hz |

| Mains requirement | E-type or Std. Schuko wall socket |

| Conection | 5 m power cord with V-lock system |

| Power | 3000W |

| Mains requirement | Std. Schuko wall socket |

CABLE REEL |

|

| Motorized Cable Reel | Yes |

| Umbilical Cable | 200m (Standard) |

LEDRig End Caps (Set of 2)