Patent applications in several countries and regions cover the proprietary and unique technology of Sewertronics Epoxy UV two-component resin. No licences have been granted to third parties. |

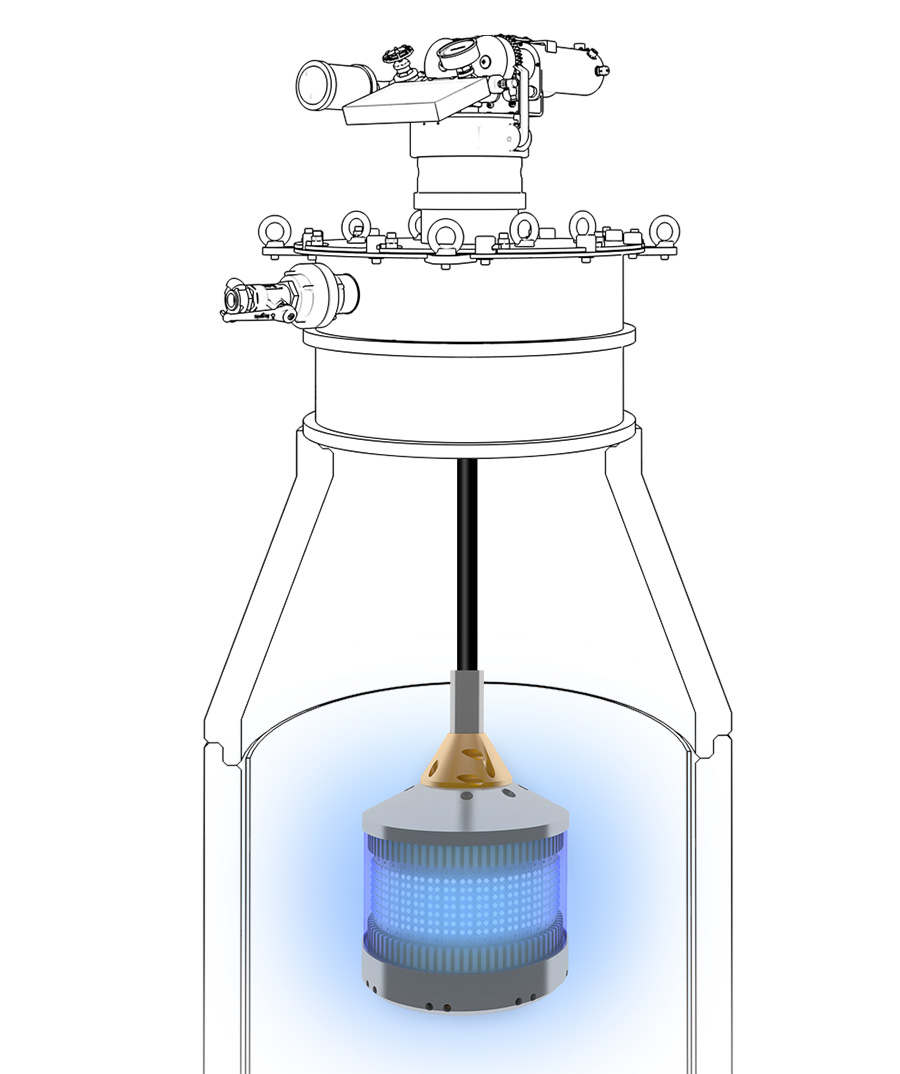

LED Epoxy two-component resin

Sewertronics has developed a unique two-component epoxy UV resin, which delivers outstanding features like the unique combination of light curing and ambient (latent) curing, ensuring total resin polymerization under any situation.

These hybrid epoxy based binder, free from volatile solvents, ensures a proper polymerization yet delivering a high degree of bonding and adhesiveness. From a mechanical perspective, Young modulus and first breaking strength exceeds the industry standards allowing to cure liners of 3.0 to 6.0 mm under any load hypothesis and hose pipe stage. Guidelines and recommendation from EN ISO 11296-4 and DWA 144-3 have been followed.

| Main features and advantages |

|---|

| - Latent curing ensures total resin polymerization under any circumstances. |

| - Low curing temperature (thermal peak) as 70ºC. |

| - Exceptional chemical resistance and Tg. |

| - Elevated mechanical properties. |

It is a highly technical product, offering bonding capabilities due to a lack of shrinkage after curing and low curing temperatures.

This resin is a two-step curing chemistry, meaning that the total polymerization of the laminate occurs in two phases. After UV LED light curing all the laminate is either 100% polymerized or in gel phase. Water infiltration would hence not wash resin away

Phase 1. UV LED light curing.

UV LED curing heads trigger the first polymerization, delivering instantly around 70% of the total mechanical properties.

Phase 2. Latent-ambient curing

After UV LED polymerization, the latent curing is triggered, gradually increasing mechanical properties during the following days and progressively increasing asymptotically the properties seeking for the 100% curing in time. This second polymerization phase ensures a perfect curing of the liner, compensating any error in the definition of the right curing speed, wrinkles shadows or any other.

Mechanical properties

This resin delivers generous mechanical properties, both in E modulus as well as first break strength values. Hereby some orientations depending on the liner cured.

| Liner type | E Modulus (short-term) |

|---|---|

| - Standard needled felt liner | > 3.000 MPa |

| - Knitted liners | > 3.500 MPa |

| - Fibre-glass liners | > 4.000 MPa |

LED Epoxy single-component resin

Single component epoxy UV resin, offering lack of shrinkage and elevated mechanical properties in every liner type. Low curing temperatures avoiding the risk of tube deformation ensuring a degree of bonding to the host pipe.

| Main features and advantages |

|---|

| - Low curing temperature (thermal peak) <100ºC |

| - High chemical resistance and Tg |

| - Elevated mechanical properties. |

Mechanical properties

This resin delivers generous mechanical properties, both in E modulus as well as first break strength values. Hereby some orientations depending on the liner cured.

| Liner type | E Modulus (short-term) |

|---|---|

| - Standard needled felt liner | > 2.750 MPa |

| - Knitted liners | > 3.250 MPa |

| - Fibre-glass liners | > 3.750 MPa |

Vinyl ester styrene-free resin

This VE resin has been specifically designed for UV cure pipe rehabilitation process. It contains methacrylate instead of styrene and offers high chemical resistance, while delivering excellent mechanical properties, both from E modulus and first breaking strength point of view.

Liner can be impregnated either at the job site or at the customer ‘s impregnation facility. In both cases traditional impregnation tables can be used.

The styrene-free vinyl ester resin is supplied in one component, so there is no need to mix resin and hardener, avoiding additional work and dosing risks. The chemistry of the resin includes a special component, a photo initiator sensitive to long-wave (400 nm) ultraviolet light.